You’ll need a motor if you’re looking to assemble a model RC plane from scratch or trying to upgrade an old one. The brushless variants are often preferred, but how can you choose the best option?

Here’s how to choose the perfect brushless motor for RC planes:

- Choose between inrunners and outrunners.

- Consider your preferred speed.

- Consider motor size in relation to the plane’s wing load.

- Choose a motor with the right power.

- Choose a motor that delivers the right thrust.

How Do You Choose the Perfect Brushless Motor for RC Plane?

I’ll cover everything you should know about choosing the perfect brushless motor and how to choose the right one.

1. Choose Between Inrunners and Outrunners

The main difference between both types of motors is the general rotation mechanism adopted in the design. Both have their pros and cons, with each one more suited to different types of RC planes.

Inrunner Brushless Motors

With Inrunner brushless motors manufacturers design the engine with the magnets directly on the shaft and the copper windings around it. Since the magnets are very close to the shaft, the result is a fast-spinning rate.

These motors are known to deliver high Revolutions per Minute (RPM) but with generally low torque. It’s why you’re likely to find them in RC helicopters. However, you can give it more torque by using a gearbox if possible. You’ll need a gearbox with this if the RC plan has sizable propellers.

Of course, throwing a gearbox into the mix gives you some things to worry about:

- They cost a fair amount of money.

- They require more maintenance.

- They are noisier.

Outrunner Brushless Motors

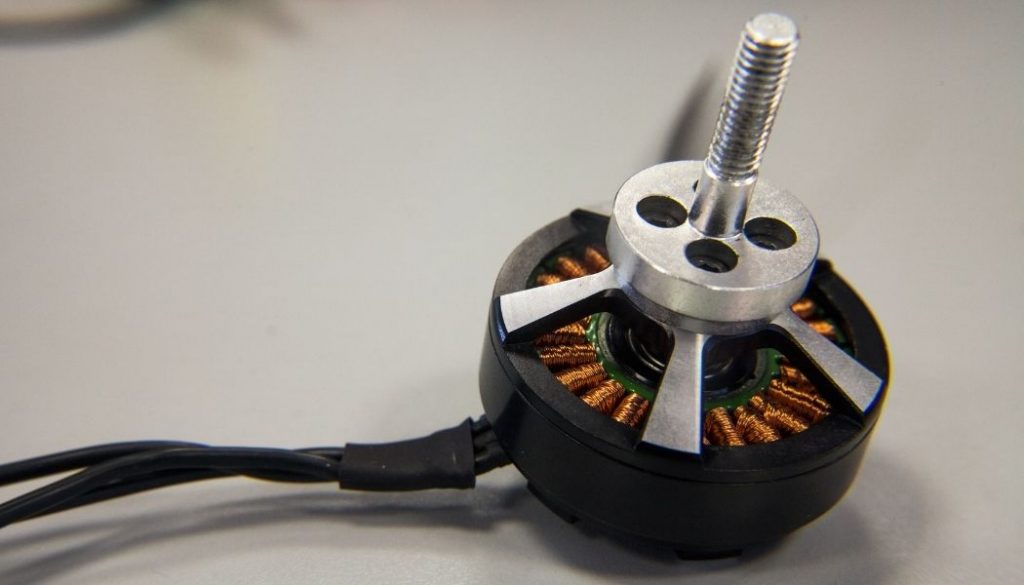

With outrunner brushless motors, you’ll find copper windings inside the engine. The shaft area often features a kind of bell containing the motor magnets. The combination of magnets and casing make it easier for the motor to spin around the copper windings.

These brushless motors work as a flywheel because the magnets are spread wide apart from the shaft, and the bell adds extra weight to the motor’s engine.

A typical outrunner motor will deliver lower RPM, but they have higher torque than inrunner motors. This means you can count on an outrunner engine to effectively spin a sizable propeller without a gearbox.

Therefore, using an outrunner brushless motor guarantees you a quieter motor and a cheaper engine that won’t require anything more than regular maintenance.

Looking at both types of brushless motors, you can decide what appeals to you the most: the power you get with a gearbox installed or an efficient and quiet operation.

2. Consider Your Preferred Speed

The brushless motor speed is directly related to how fast you want your RC plane to go. To accurately compare speeds, you need to pay attention to the revolutions per volt (KV). This is the number of times a motor will turn for every volt fed to it, assuming no load attached.

When choosing a brushless motor for your RC plane, you have to pick between a high KV and a low KV.

How do high and low KV differ?

A higher KV motor will spin faster per volt compared to a lower KV motor. If your RC plane’s battery is a bit smaller, I’ll advise going with a higher KV motor to take better advantage of every volt. This is especially true if you intend to use the RC plane in competitions.

If you are not under any voltage constraints, you can use a lower KV motor and rely on the higher voltage delivered to deliver higher RPM.

3. Consider Motor Size in Relation to the Plane’s Wing Load

The physical size of a brushless motor is important because it’s a determinant for torque. You can see the size of a brushless motor by looking at the number on it.

You’re likely to find something like “25-06.” The number before the dash references the width of the motor, while the one after is a measure of the height.

You can also find the number on the packs for the brushless motor. A higher width number signifies a motor with more torque. Such motors have more leverage.

Now, before you settle for a motor size (and torque by extension), you need to look at the weight that an RC plane carries (wing load) and stall speed.

The wing load is the plane’s loaded weight divided by the wing area. By knowing the plane’s wing capacity, you’ll have a better understanding of the plane’s lift-to-mass ratio. This ratio plays an important role in everything ranging from how the plane climbs to how much load it can carry.

NOTE: If your plane has a heavy wing load, you’ll need to choose a brushless motor that can deliver the right amount of torque for it—without overshooting the right weight for the RC plane overall.

Generally, I prefer maintaining a light wing load and, by extension, a lighter RC plane. You’re sure to get a comfortable flight with this configuration because a lighter plane reduces the likelihood of the aircraft stalling.

4. Choose a Motor With the Right Power

The power of the brushless motor is as important as the size. The overall power is often denoted in Watts (Voltage x Amps). A higher number often equals a more powerful motor.

While checking the power, it’s important to look at how many Amps the motor pulls. This will help you to find the right Electronic Speed Controller (ESC). Your ESC rating should be 50% higher than your motor’s AMP rating. So, if the motor pulls 40A, you’ll need a speed controller with a 60A rating.

Again, as I’ve mentioned above, you’ve got to consider a few things before settling on a power rating for your brushless motor.

5. Choose a Motor That Delivers the Right Thrust

The thrust from the motor determines how fast your plane will take off for a flight. Here, the common determinant is the weight of your RC plane. You should choose a brushless motor that can deliver thrust that matches the weight of your plane.

KEEP IN MIND: A plane that weighs 3lbs (1.36 kg) needs a brushless motor that can deliver 3lbs (1.36 kg) of thrust. That’s the only way you can achieve vertical lift. Otherwise, the plane will never leave the ground, or it may crash when you attempt a takeoff.

Brushless Motors Suggestion

Brushless motors are synchronous motors that rely on DC power. I won’t dwell on the scientific details as you can get most of it on Wikipedia or this page. However, it’s a vital part of an RC plane because it affects everything, including the flight, takeoff, and landing. It controls the plane’s speed and overall movement.

Below is one of my favorite brushless motors currently available for your RC plane.

Goolsky SURPASS 1400KV RC Motor

If you’re looking for a brushless motor that’s powerful enough for an RC plane with a high wing load, Goolsky RC motor should be high on your list. It has a 1400 RPM/KV voltage rating and a high torque design.

A special feature I should mention is the aluminum heat sink can, which ensures you don’t have to worry about your plane overheating while in use. Thanks to precision engineering, the motor delivers smooth performance at all times, which ensures efficient energy conversion.

Read Next

- How do You Clean a Brushed RC Motor?

- Main Differences Between Brushed and Brushless RC Motor

- What Happens if Your RC Plane is Nose Heavy?

- How Much Do RC Planes Weigh?

- How Does RC Aircraft Steering Work?

- Do You Need a License To Fly RC Planes in the US?

- How Long Can RC Planes Fly?

- How To Fly an RC Plane?

- How To Buy and Fly an RC Plane?