Choosing the right type of ESC for your RC car can be confusing with all the overwhelming specs. However, if you select the wrong ESC, it can damage your car and ruin your experience. So, you’re probably wondering what an ESC is and how you should choose the right one for your RC car.

An ESC is the brain of your RC car, controlling its speed, brakes, and other functions. To choose the right ESC, you need to make sure it matches the motor and calibrate the ESC by setting the high and low throttle positions. LiPO and NiMH batteries are commonly used in ESCs.

This article will cover everything you need to know about ESCs, how they work, and how to choose the right one for your RC car. I’ll also explain how you can diagnose your ESC’s problems.

What Is an ESC?

If you have a radio-controlled car, it can’t work without an ESC (Electronic Speed Control), which virtually functions as the car’s heart and brain.

An ESC allows you to control the car’s speed and power. When you move the stick on the throttle, the receiver picks up the signal from the transmitter, decodes it, and then sends it to the ESC. The ESC converts this signal and then sends it to the motor to move the RC car.

The ESC functions in a variety of ways, depending on how sophisticated it is. It can be as simple as a switch to turn the car on and off. In such a case, you don’t have much control over the speed.

Other models have sticks to reduce or decrease the car’s speed by moving the stick along their axis. They send power pulses from the battery to the motor. If the pulses are narrow, there will be a long gap between them, causing the motor to slow down. Conversely, wide pulses have very small or no gaps, making the motor run fast.

The ESC may be in the throttle receiver’s control channel as a separate unit or be an integrated part of the receiver itself. Most RC cars use the second model.

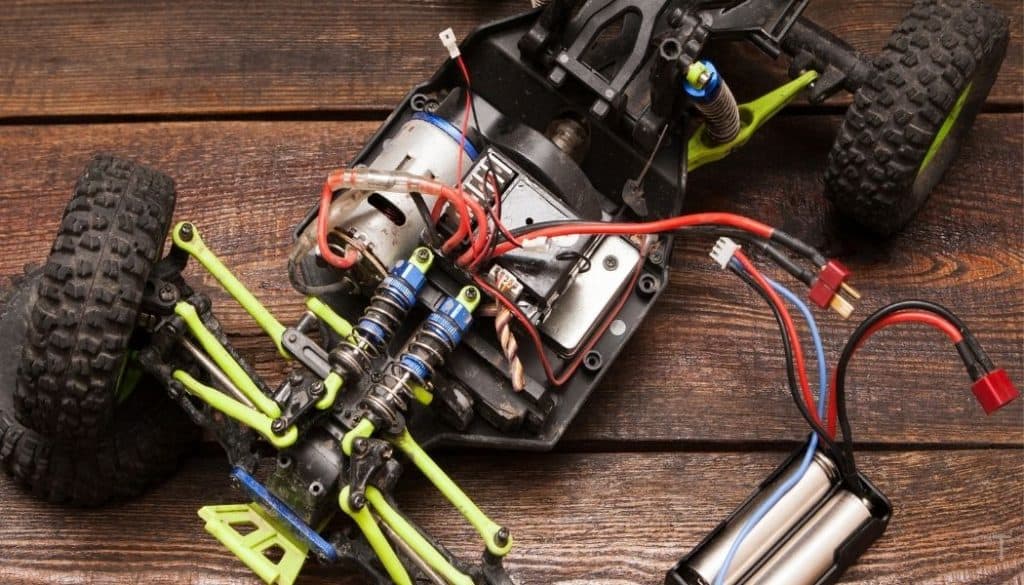

ESC Components

An electronic speed controller has three essential components: a processor, a voltage regulator, and a switch.

- The processor’s job is to decode the signals it takes from the receiver and regulate the motor’s power.

- The switch is a transistor that observes the motor’s voltage and current and checks the battery. It also controls the current flow that goes into the throttle.

- The voltage regulator powers the servos by sending a specific amount of power to the receiver. This amount of power is typically 5v 1Ah.

A BEC (Battery Eliminator Circuit) can replace the voltage regulator and reduce the battery’s voltage so that it can run the motor. It eliminates the need for a different battery to run complex sets of cables from the device’s battery, powering the device directly.

When you need full power, the BEC can prioritize the power supply. So, if the battery reaches its minimum voltage, the BEC ensures the power doesn’t come entirely from the battery. This way, some power will be reserved for critical conditions.

Most ESC units have integrated BECs these days. However, if your ESC doesn’t come with a BEC, you can use a UBEC, which stands for Universal BEC, a standalone unit that provides power to the ESC. In this case, you should disable the integrated BEC by removing the wire (typically red) from the ESC’s output servo.

Even if your ESC has a built-in BEC, you can use a UBEC to reap its benefits. A UBEC is more efficient and more reliable than an integrated BEC because it directly hooks up to the main battery. Plus, it doesn’t overheat due to big input/output differences, and it’s much safer in providing power.

Types of ESC

If the ESC comes built-in on the RC car, you don’t need to worry about its specs. But if you want to make a customized ESC for your car, you should consider a few factors.

First and foremost, note that there are two kinds of motors that work with ESCs: brushed and brushless.

Brushed Motor

A brushed motor contains an armature, the part of the motor that rotates and consists of poles, a terminal, and a commutator.

Poles are, in effect, an electromagnet made of wires wrapped around a piece of metal. Most motors typically have three poles connected to the armature.

The terminal is where the poll’s copper wire attaches. And the commutator is a switch on the armature that regularly reverses the currents entering the poles. This way, it maintains the rotation of magnetic fields.

Ho does Brushed Motor work?

- The main parts of brushed motors are brushes. They’re tabs built in the motor cap connected to the battery, and when the armature rotates, they come into contact with the commutator’s plates. The plates are the same number as the armature’s poles.

- When the brushes touch the plates, a pole gets charged. This is because there are two magnets on the outer shell of the motor with opposite polarities.

- When the pole gets charged, one of these magnets attracts it, and the other repels it.

- The commutator switches the pole’s polarity every time it brushes against the magnet. This way, it enables the commutator to act as a switch.

- This process continues as long as the motor has power coming into it.

A brushed ESC turns the voltage on and off several times per second to control the speed at which the motor turns. It increases the speed by increasing the amount of time the voltage is on and decreasing the time the voltage is off.

Brushless Motor

A brushless motor essentially works the same as a brushed motor. The only difference is that the poles are stationary, and the magnets are on the rotating part of the motor while they’re stationery in the brushed model. The stationery poles eliminate the need for brushes, and the ESC switches the poles’ voltage.

A brushless motor has a specific rating called KV, which is a measure of the motor’s maximum rpm (round per minute) per volt.

TIP: If you have a 3000kv motor, it turns 3000rpm per volt at maximum throttle. This motor, with a 3000KV rating, is a fairly slow motor with high torque. So, you should look for one with a KV rating of 8000 and higher.

How To Tell the Difference Between a Brushed and Brushless Motor?

Telling the difference between the two types of motors is easy. All you need to do is to look at the wire leads and count them. If there are three wires, the motor is brushless, while a brushed motor only has two wires.

Brushless motors are better than brushed ones because they reduce the commutator wear and tear due to the absence of rotation and physical friction. Plus, they produce more power relative to their weight because there’s no friction.

NOTE: The key point about these two types of motors is that they're not interchangeable. So, if you have a brushed motor, you need a brushed ESC, and for a brushless motor, you must use a brushless ESC. If you choose the wrong type of ESC for the motor, you'll run the risk of destroying both the ESC and the motor.

Other Factors To Consider in Choosing an ESC

The size of the ESC is a major factor to consider. You should make sure the ESC fits into the car properly.

It’s better to opt for waterproof ESCs with extra protection. However, if it’s not waterproof, you can waterproof it yourself.

- You can encase your ESC in a waterproof box or cover it as a homemade solution. Many people recommend putting the ESC in a balloon because a balloon is a tight fit and cheap. However, it may cause your ESC to overheat and melt the balloon itself.

- Instead, you could put it inside a plastic box or build a shield out of scrap Lexon. Alternatively, you can carve up a drink bottle and hold everything in place using duct tape.

- Another effective method is to use Plasti Dip Multi-Purpose Rubber Coating Aerosol from Amazon. This coating shields items from moisture, corrosion, and acids. It also makes them easier to grip and reduces slippage.

To apply it, take the ESC out of its case and wrap duct tape all around the cooling fans. Then, cover the whole system with Plasti-dip and leave it to dry for 12 hours. This way, you’ll form a thin film around the whole ESC, making it waterproof.

NOTE: This method will void any guarantee on your items.

How To Program Your ESC?

To program your ESC, you need to check the instructions that come with the user manual. Programming lets you calibrate the ESC to respond to certain throttle input ranges, including the on and off and high and low ranges. These calibrations indicate what PWM values correspond to which command.

Pulse-width Modulation (PWM) is a method that gives analog results with digital tools. You define the “on” command as the “full pulse width,” and other commands fall within this range.

Regardless of the ESC’s brand, the first thing you should do is to calibrate your throttle range. That’s because different transmitters come with different throttle ranges.

How to adjust throttle range?

- To adjust the throttle range, bring the throttle to the highest position and hook up the battery to the ESC. Then, you’ll hear a beep suggesting the device has confirmed the highest range.

- After that, move the throttle back to the lowest position. You should hear several beeps that show the number of battery cells.

- Finally, a long beep will indicate the device has recognized the lowest range.

ESCs are also programmable using program cards. You can check if a programming card is available for the ESC before buying it. They help you program the ESC and make your desired changes faster and easier. Plus, they’re reusable and cheap.

You can upgrade your ESC’s software easily, even if your ESC is old. This way, you can have all the new features offered by the manufacturer. However, the programming cards and cables only come from the corresponding manufacturer, and you can’t use one manufacturer’s programming card for another’s ESC.

ESC Batteries

Different ESCs work with different kinds of batteries. Some of them can run on various batteries, whereas others need to use specific kinds.

NiMH (Nickel-metal Hybrid) batteries and Lipo batteries are the most common types used to power ESCs.

- Lipo batteries need more maintenance because they could cause a fire if you overcharge or over-discharge them. Extensive physical damage can also be a fire hazard. That’s why you should always make sure to keep your batteries at 2.9 v per cell at the minimum.

- If your RC is Ready to Run (RTR), it probably comes with a NiMH battery because it’s cheaper and more reliable. But you can upgrade to LiPO once you’ve got the hang of riding your car to get better performance.

- It’s easy to identify the battery’s chemistry (LiPO or NiMH) by looking at it. A NiMH battery looks pretty much the same as a rechargeable AA battery in a round cell.

- On the other hand, a LiPO battery comes in a flat and rectangular cell. The good thing about these batteries is that they come in various dimensions, making them fit different RCs. If your car has a rounded mount to hug a NiMH battery by default, you can use a LiPO battery with a round hard case.

- If it goes below that, the battery can’t get fully charged again. Plus, it may swell and cause a fire. That’s why you should use an ESC with automatic cutoff. This mode will keep the battery safe and doesn’t let it drop below a critical level. The cutoff voltage depends on the battery and the RC car. The ESC automatically detects the battery’s voltage and sets the cutoff voltage accordingly.

Choosing the Right Battery

If you want to choose the right battery for your ESC, you need to look at the specifications. These specs give you the type of battery, the voltage, and the amp rating needed to run the motor. You can’t exceed the voltage and current rating specified on the ESC. The speed controller tells you the number of volts you can send through it, expressed in the number of cells in the battery.

The next thing to consider is that the motor will not draw more current than the ESC’s maximum amps. The discharge rating, the battery voltage/cell count, and the battery’s capacity are the three main features you should know to pick the right battery. The battery’s capacity, measured in milliamp per hour, indicates the amount of power the battery can hold.

You should also know how much current you can draw from your battery without exerting any pressure on the battery. Shown as a “C” rating, the common ratings are 10C, 20C, and 30C. Your choice of rating should be more than the motor’s maximum current draw.

It’s better to choose a battery with at least 5A higher capacity than the motor’s maximum rating. There are different calculators online that you can use to determine the right battery rating and other essential factors to help you choose a suitable battery.

Depending on the type of ESC, you may be able to use a LiPo battery instead of a NiMH. Although Lipo (lithium polymer) batteries need more maintenance, they can provide more power-to-weight ratio, leading to better performance and speed.

The most recent type of battery is LiHV batteries that are a kind of lithium battery with higher voltage. While a typical lithium battery’s peak voltage is 4.20 volts, it’s 4.35 for a LiHV battery. This higher voltage increases the run times and power while reducing internal resistance.

To reap the benefits of this new kind of battery, make sure the ESC can accept the LiHV maximum cell count.

How To Diagnose an ESC

Like any other electronic component, you may experience issues with your remote car’s ESC. The problems can be any of the following:

- Slow top speed

- Poor braking

- No forward movement

- Faulty or strange behavior

If you’re sure the problem is with the ESC—and not the motor—you can check a few things to diagnose the problem.

- The first thing to check is the ESC’s physical condition. Make sure all the soldered wires are ok, and no wires are faulty or broken.

- Does the car sound or smell weird when it powers up? Sometimes, dirt and debris can cause poor contact and electrical efficiency. So, make sure everything is clean.

- Make sure the motor isn’t faulty because a bad motor can damage an ESC. You can make sure the motor and the ESC work by replacing them with one that you’re sure isn’t bad. If your problem persists, you can be sure that the ESC is in good shape and the culprit is something else.

- Make sure the ESC is getting enough power using a multimeter to check the voltage. Check the battery to ensure it’s not dead.

- Sometimes, the problems are due to misconfiguration on the transmitter throttle system. Try to readjust the throttle by calibrating the ESC.

If none of the mentioned solutions seem to work, or you’re sure that the problem is a broken piece of hardware, you’d better contact a repair service.